What problem are we solving?

Most basic electrolyzers orient the plates vertically in the tank, allowing buoyancy and gas bubble collisions to dislodge gas bubbles from the anode and cathode plate faces.

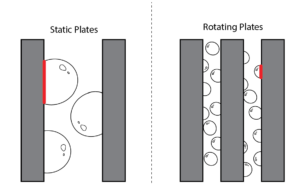

It is important to understand that as the bubble form on the plate surface (anode or cathode), the area “under” the gas bubble is deactivated (see red highlight in Figure 1). Since the gas bubble is keeping water from touching the plate surface under the bubble, no electrolysis can occur in the area. The gas bubble can only grow as a result of gases captured at the edge of the bubble, where water may contact the plate or via other hydrogen atoms in the water. Until the bubble dislodges from the plate surface, no more gas production can occur in that surface area. The bubble is acting like a dome, keeping water from touching the electrons on the surface of the plate, shutting down the electrolysis process in the dome’s circumference.

This deactivation of plate surface is happening consistently across all plate surfaces, for both hydrogen and oxygen atoms. While gas production is under way, the more gas produced, the less plate surface is available until the gas bubbles detach due to buoyancy. If one were to watch an electrolyzer, one would see small bubbles form on all plate surfaces, growing until they float to the surface.

The gas bubbles can also end up deactivating an adjacent plate surface if the plates are too close together. If the plates are too close, the gas bubbles may grow to a size that allows them to come in contact with the face of plates across the plate gap, deactivating plate surface on two plate faces until buoyancy causes detachment. This potential for dual plate deactivation reduces the number of plates that can be put into an electrolyzer tank as the plate proximity is limited by the size of the gas bubbles produced. This limit in plate proximity reduces the overall gas production capability of any electrolyzer design.

Why Centripetal Force?

To address all of the aforementioned limitations; plate surface deactivation, dual plate deactivation, and gas separation efficiency, CRD employed centripetal motion. Spinning the plates creates centripetal forces on the gas bubbles forming on the plate faces. This centripetal force, added to the forces of gravity and buoyancy, cause the bubbles to dislodge from the plate surface faster. Since the bubbles detach faster, the bubbles are smaller. These smaller bubbles, when forming on the plate surface, have a smaller deactivation surface, allowing more bubbles to form on the plate surface. Instead of large bubbles forming and deactivating large amounts of plate surface, the centripetal forces cause the bubbles to detach when they are much smaller, never allowing the bubbles to grow to larger sizes.

The smaller bubbles and faster detachment times allow more of the plate surface to be used in the same period of time. Smaller bubbles can also use more plate surface as they can cover more area due to decreased spacing, helping to achieve higher plate surface usage while simultaneously freeing up plate surface at a far higher rate. This achieves a dual efficiency as more water molecules are exposed to the anode and cathode surfaces faster.

The smaller bubbles and faster detachment times allow more of the plate surface to be used in the same period of time. Smaller bubbles can also use more plate surface as they can cover more area due to decreased spacing, helping to achieve higher plate surface usage while simultaneously freeing up plate surface at a far higher rate. This achieves a dual efficiency as more water molecules are exposed to the anode and cathode surfaces faster.

Using centripetal force to dislodge gas bubbles earlier in the formation phase also provides the additional benefit of helping to remove potentially larger bubbles forming at the inner radius of the spinning plates as the centripetal force is lower the closer one gets to the center of rotation. The centripetal force causes all the bubbles formed to rush to the center of the chamber. As a result, the smaller bubbles forming at the outermost radius will dislodge bubbles forming at inner radii. This provides additional conditions that will help quickly dislodge gas bubbles forming closer to the center of rotation, again freeing up plate surface for more electrolysis to occur faster.

Additionally, the smaller bubbles allow the plates to be placed closer together in the tank. Since larger bubbles no longer form, the gap between plates can be reduced, as the likelihood of dual deactivation of plate surface due to large bubbles spanning the plate gap is reduced. With the plate gap reduced, the number of plates within the same electrolyzer footprint (3-dimensional area) can be increased. Increasing the number of plates increases the amount of gas that can be produced within the same footprint.

If you would like to learn more or cooperate with Cambridge R&D on future research in this area, please feel free to contact us.